Key CNC Machining Jobs That Drive The Manufacturing Industry

CNC machining is a foundational part of Canada’s manufacturing landscape, supporting high-stakes sectors like aerospace, medical, nuclear, defence, and construction. As more industries turn to CNC for its speed, cost efficiency, and precision, the demand for skilled professionals continues to rise. Whether you’re just starting out or considering a shift into manufacturing, CNC machining offers […]

Innovative Strategies in Manufacturing for a Sustainable Environment

In the not-so-distant past, companies practicing sustainable manufacturing methods were considered outliers—those willing to trade a bit of margin for environmental responsibility and some good PR. Back then, sustainable machining often meant little more than recycling metal scraps. Everything else was business as usual. Fast forward to 2025, and sustainable manufacturing isn’t merely nice-to-have; it’s […]

The Real Cost of Quality in CNC Machining – Why It Pays to Invest Upfront

Every new product requires a specific level of quality that businesses must factor into their budget. For everyday consumer goods, this might mean ensuring a part works just long enough to outlast the warranty period or achieving the highest level of quality possible for a given price. But for Ben Machine customers, the expectations are […]

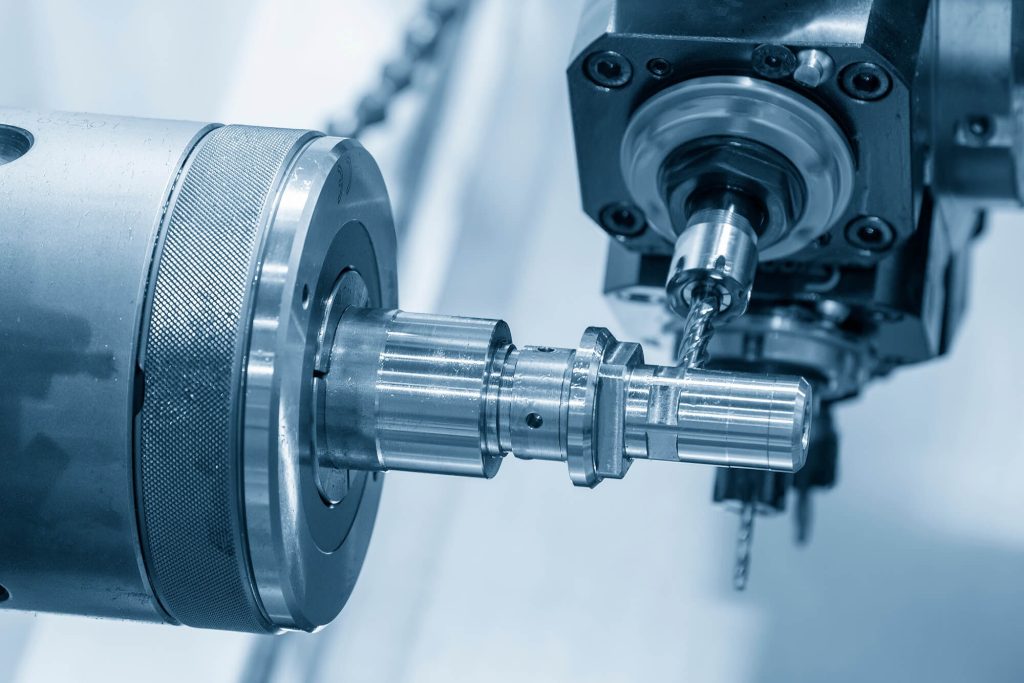

Precision CNC Machining for Aerospace Components and Landing Gear Control Systems

CNC machining plays a pivotal role in the ever-evolving aerospace industry, where precision, reliability, and repeatability are non-negotiable. Whether it’s the structural components of an aircraft or the systems that support safe takeoffs and landings, CNC machining brings the high levels of accuracy and complexity that aerospace manufacturing demands. Aerospace components require tight tolerances, exotic […]

Strategic CNC Machining Applications Across Industries – With a Growing Focus on Canada’s Defence Sector

CNC machining applications have transformed modern manufacturing—from tiny micro-components to large-scale structural parts. But beyond general manufacturing, this precision technology plays a vital role in strategic sectors, particularly in defence and critical infrastructure. As Canada commits to increasing defence spending to 2% of GDP—amounting to an estimated $9–10 billion—the pressure is on to expand and […]

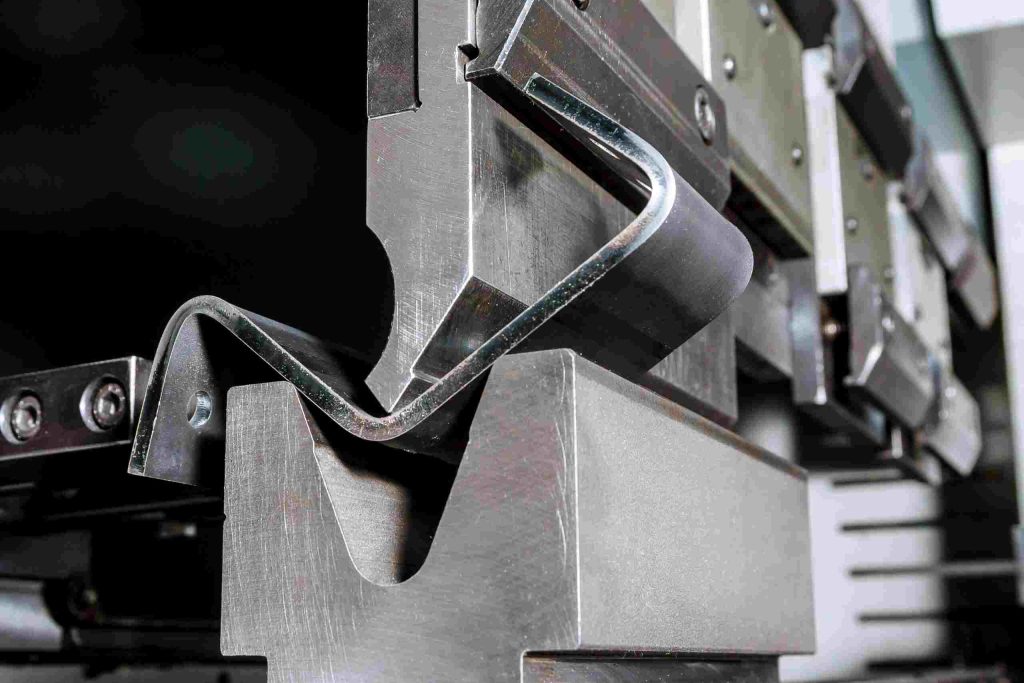

Precision Sheet Metal Fabrication: A Comprehensive Guide to Cutting-Edge Processes

Precision sheet metal fabrication is the process of transforming flat sheets of metal—such as steel, aluminum, copper, or brass—into finished components through cutting, bending, forming, and assembling. This essential manufacturing method plays a critical role in industries like automotive, aerospace, electronics, construction, and medical devices. In this guide, we’ll explore how modern fabrication techniques have […]

The Future of CNC Machining in Military and Defence

CNC machining has been vital to the military and defence sectors for decades. It all started after World War II, when the demand for complex parts was high. As technology advanced, so did the potential of CNC machining, with emerging innovations set to redefine the industry. Over the years, CNC machining has become more advanced […]

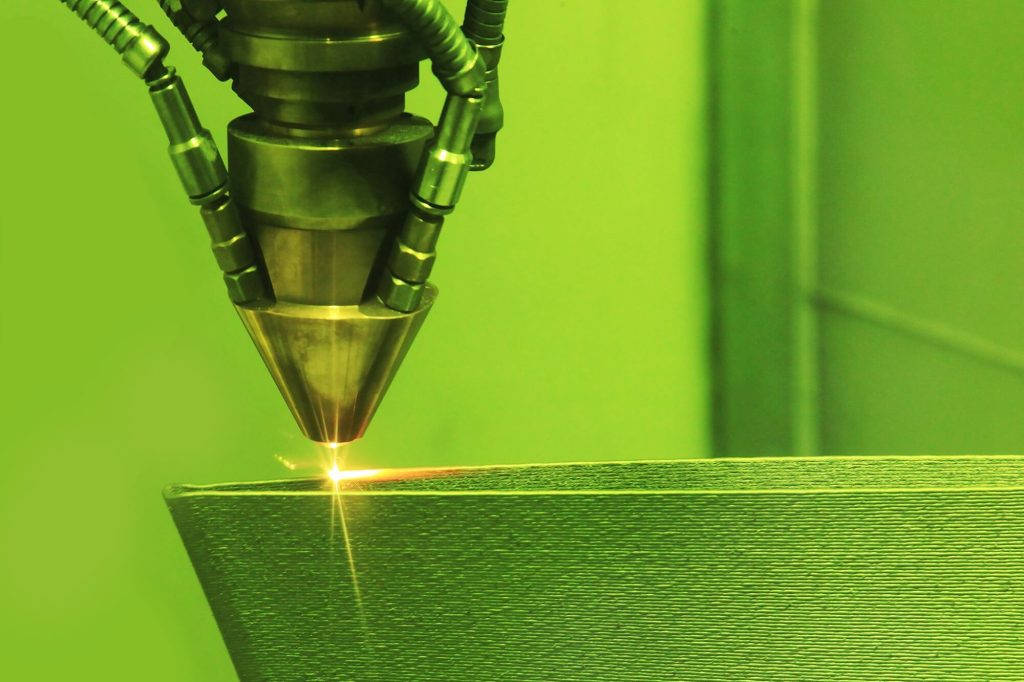

Additive vs. Subtractive Manufacturing: A Strategic Partnership in Modern CNC Operations

Manufacturing today is no longer an either-or decision between traditional CNC machining and 3D printing. Instead, innovative manufacturers are finding value in combining both additive and subtractive manufacturing techniques. By combining these methods strategically, it’s possible to accelerate product development, minimize waste, enhance part quality, and reduce production costs. Additive manufacturing (AM), also known as […]

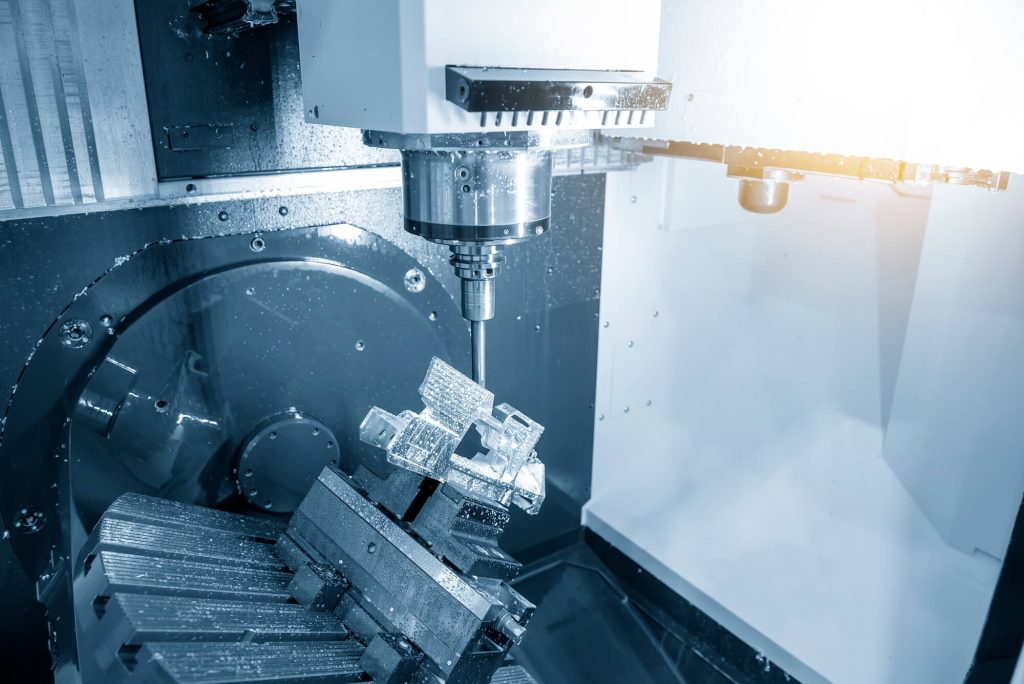

Maximizing CNC Production Efficiency: The Power of Lean Principles

The typical CNC machine shop, when faced with the need to increase capacity, immediately expands physically with more machinery and extra floor space. However, these same shops could have accommodated more work by optimizing their existing space and improving efficiency through several strategic approaches. Space Optimization Strategy Ben Machine has configured its operations to run […]

The Hidden Costs of Low-Volume Production and How to Mitigate Them

Low-volume production refers to manufacturing a relatively small number of units—typically between 10 and 500—though exact quantities can vary depending on the industry and technology involved. Manufacturers often use a low-volume approach to bridge the gap between prototyping and mass production. Companies also use it when products are extremely expensive and sales volumes are low […]